European Commission, France

Challenge

A major amount of the energy consumed in industry is wasted as lost heat, which represents millions of tons of CO₂ being produced uselessly.

Innovation

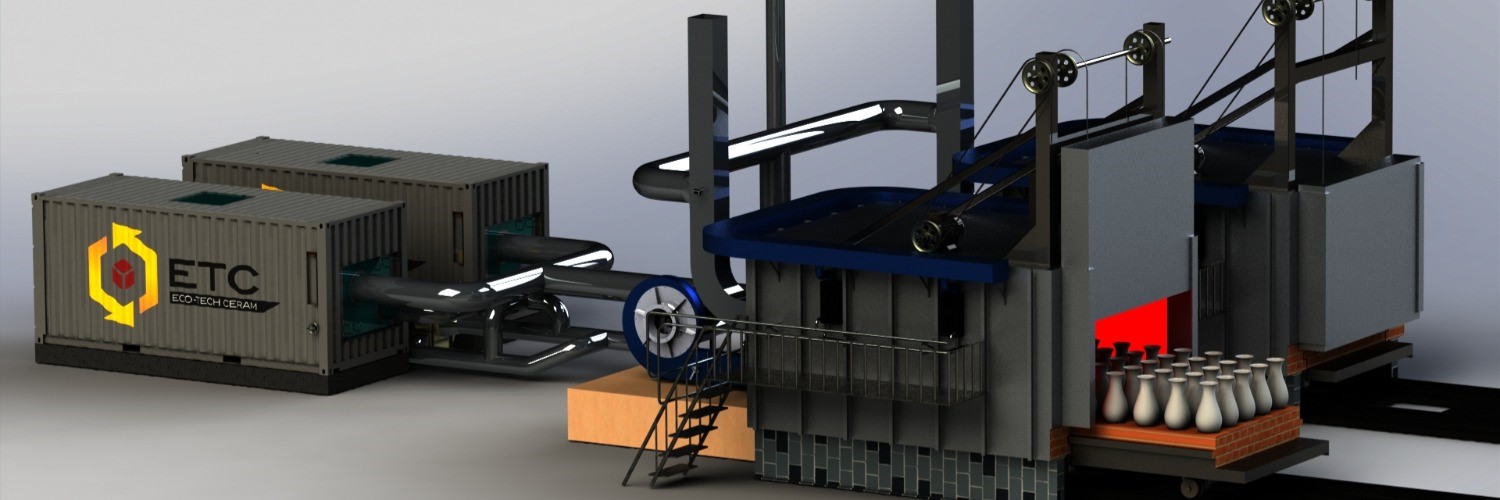

Eco-Tech Ceram’s solution recovers the heat contained in industrial exhaust gases and stores it in refractory ceramics made from industrial by-products. This accumulated heat can either be used as a heating source – hot air at constant temperature level is provided (up to 1000 °C) – or can be converted into electricity.

The solution is based on resource-efficient materials sourced from industrial waste and then applied to waste heat recovery in industry, thereby contributing to a circular economy. Other applications such as heat storage for smart cities are possible. The solution is modular and designed to be “plug & play”; it can be used at different temperature levels and energy storage capacities, and is housed in a portable container, which makes it easily transportable for use in multiple applications.

Impact

In 2019, Eco-Stock’s development reached a critical point: a demonstrator was installed in January 2019 and the first industrial unit was sold in April 2019. These advances allowed the economic profitability to be measured and confirmed, along with energy and environmental aspects. One cycle is equivalent to one petroleum barrel saved, one unit can reduce/store 2 GWh/year on average, one cycle reduces 0.4 tonnes of CO₂, and one unit can save 400 tonnes CO₂/year on average in a waste heat application.

Potential

Funding, investors, new clients, visibility and partners in Europe, China, India, and North America are some of the forms of support needed to maximise the impact of this technology.